-

3-roller type Aluminum and aluminum alloy Rod CCR Line

Application: This production line adopts process of continuous casting and rolling to produce Round Aluminum rod or aluminum alloy Rod for Electrical Purpose.

Raw material: Primary aluminum ingots/sow/ electrolytic aluminum molten/aluminum scrap from wire or cable

Fuel: NG/LPG/LDO/FO/COAL GAS

Rolling mill Lubricant: Rolling mill gears are lubricated by gear oil

Bearings and rollers of rolling stands are lubricated by emulsion oil

-

25-48t/h High Speed Cathode Copper Rod Continuous Casting and Rolling Line

Application: High speed Full-2 Roller Type Copper Rod CCR line is used for producing high quality low oxygen copper rod for electrical purpose.

We design this line combined with the world’s advanced SCR and Morgan technology, but we improve many systems and try to help the customer to reduce investment to the maximum extent.

Fuel: NG, LPG

Raw Material:

Copper Cathode Electrolytic Grade A is required, the copper purity should be 99.975%-99.99%, the 1st grade scrap copper (barely) can be mixed, but the percentage is better no more than 10%-15%.

-

2-roller Type Copper Rod Continuous Casting and Rolling Line

Application: This production line is used for producing φ8mm copper rod. However, the rolling mill is composed of roughing mill and finishing rolling, and the mill type is full 2-roller type driven by individual motors.

Fuel: NG, LPG, LDO, FO, COAL GAS

Raw Material: Copper Scrap, Cathode

1) Using red copper scrap as the raw material, the mixture ratio is as the below:60% of the 1st grade copper adds 40% of the 2nd grade copper.

2) If adopt the cathode as raw materials, the Copper Cathode Electrolytic Grade A is required, the copper purity should be 99.975%-99.99%, the 1st grade scrap copper (barely) can be mixed, but the percentage is better no more than 10%-15%.

3) The raw material mentioned above is only for reference, it depends on the requirements of copper rod quality and technology.

-

3-roller Type Copper Rod Continuous Casting and Rolling Line

Application: This production line is used for producing φ8mm copper rod. It has simple structure, high production efficiency, low energy consumption, excellent product quality and high return on investment.

Fuel: NG, LPG, LDO, FO, COAL GAS

Raw Material: Copper Scrap, Cathode

1) Using red copper scrap as the raw material, the mixture ratio is as the below:60% of the 1st grade copper adds 40% of the 2nd grade copper.

2) If adopt the cathode as raw materials, the Copper Cathode Electrolytic Grade A is required, the copper purity should be 99.975%-99.99%, the 1st grade scrap copper (barely) can be mixed, but the percentage is better no more than 10%-15%.

3) The raw material mentioned above is only for reference, it depends on the requirements of copper rod quality and technology.

-

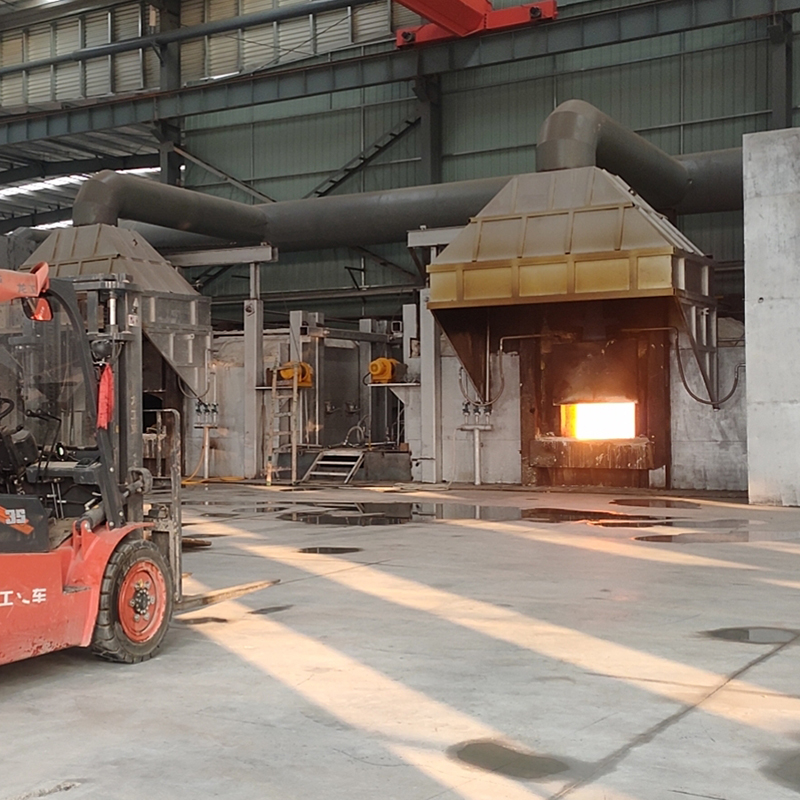

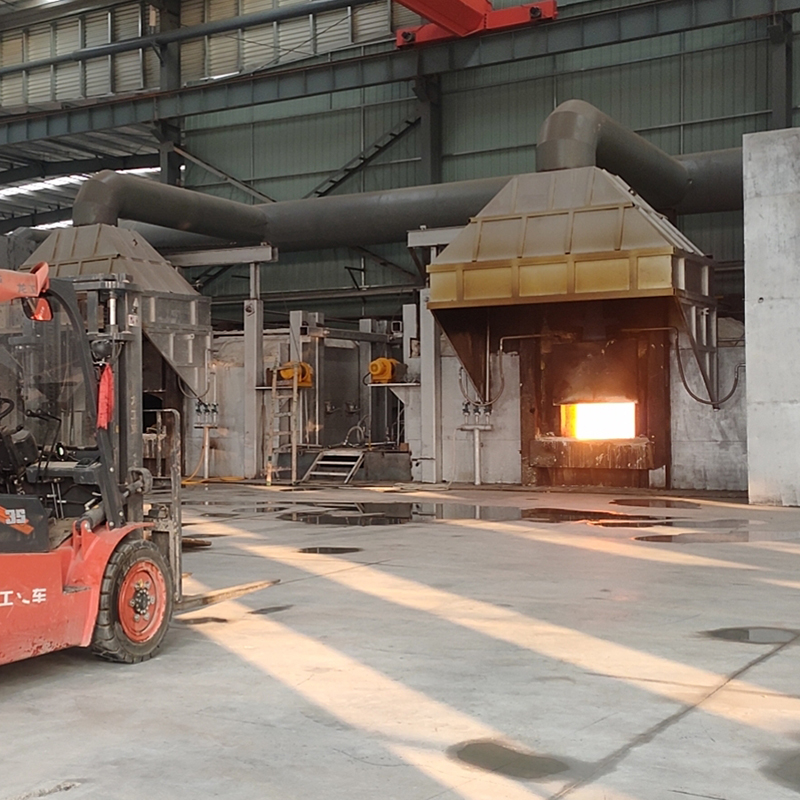

Melting and Holding Furnace

Our company has been meticulously committed to the R&D of special melting furnaces for a longer time. Rely on strong technical force and innovative design concept, we build our design purpose: energy-saving, reduce fuel consumption, improve production efficiency and product quality, improve working conditions, reduce environmental pollution, ensure the safe and reliable operation of the equipment and prolong the service life of the equipment.

In addition, in order to ensure the integrity of the casting and rolling production line, our company also provide high temperature combustion system, Regenerative combustion system, rotating Regenerative air preheater, silicon carbide metal combined air preheater, combustion fan, on-line degassing and filtration device, aluminum molten transfer ladle, etc. Except the above equipment, our company can not only provide the customized designation, manufacturing and construction according to user’s requirements, but also provide old furnace modify and energy-saving technical transformation, recommend the optimal scheme combined with the technological requirements of customers.

-

Cathode Shaft Melting Furnace and Tilting Holding Furnace

Application: The copper cathode shaft melting furnace is widely used for copper cathode smelting. The furnace has low maintenance rate, less equipment input, rapid convergency, and the capacity can be designed as the customers ‘need

Fuel: NG, LPG, LDO

Raw Material: High quality Copper cathode. The high-quality copper scrap also can be accepted, the utilization can be 20%-30%. But if the final copper rod will be used for fine wire drawing and electromagnetic wire (high quality enameled wire), we suggest the raw materials should be the copper cathode (LME Grade A)

-

Copper Scrap Tilting Refining Furnace

Application: The Copper scrap tilting refining furnace is widely used for copper scrap smelting. Because of good adaptability to raw materials, it also can be used as anode copper smelting. The refining furnace has low maintenance rate, less equipment input, rapid convergency, and the capacity can be designed as the customers ‘need (3T-60T)

Fuel: NG, LPG, LDO, FO, COAL GAS

Raw Material: Copper Scrap

-

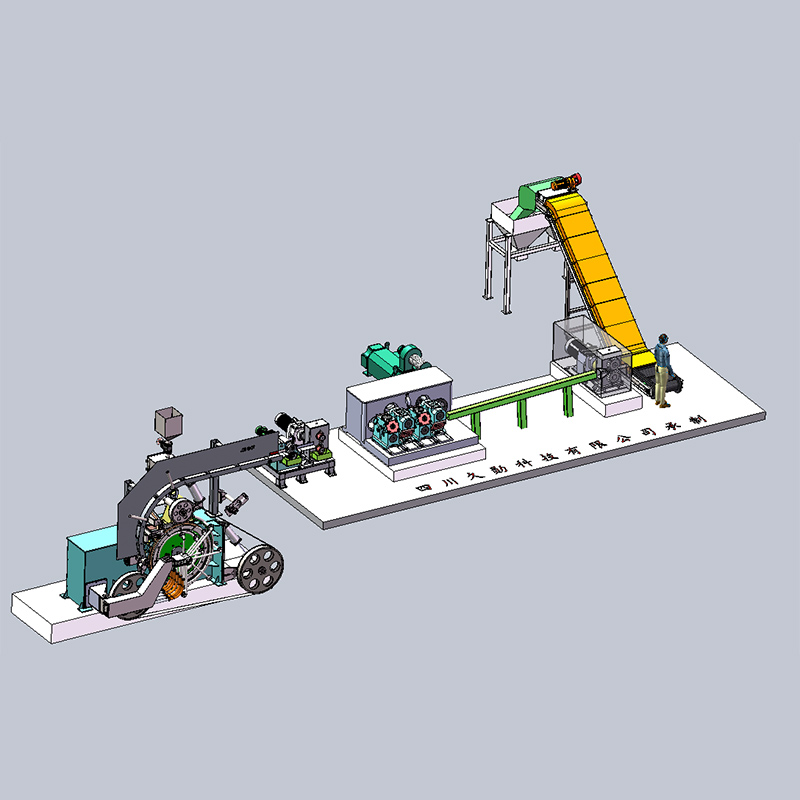

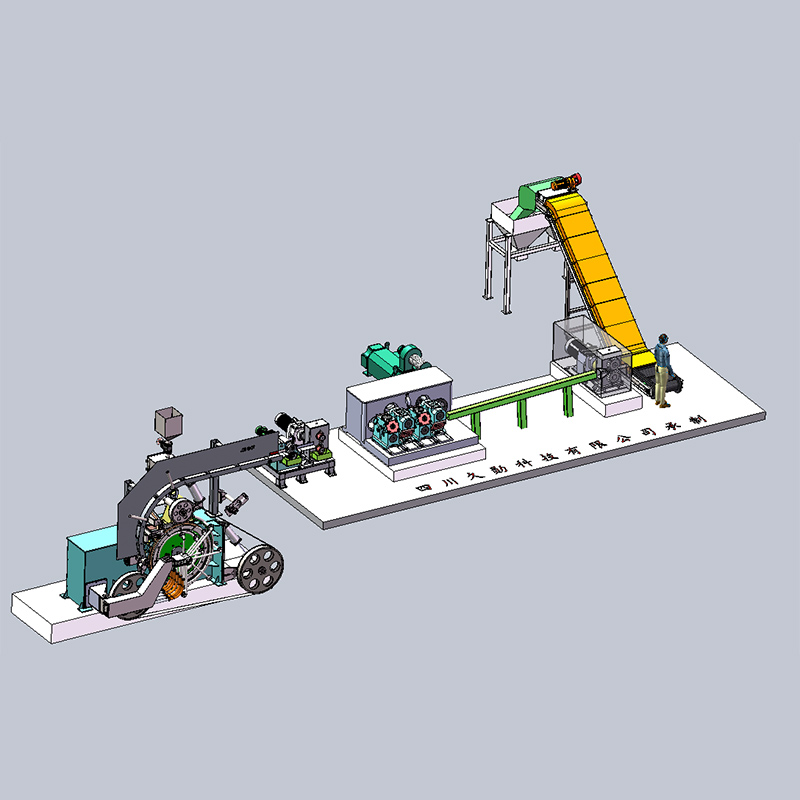

Aluminum Cut Wire rod Shot Production Line

Application :The typical Continuous Casting and Rolling Line is used for producing all kinds of deoxidized aluminum products, such as aluminum shots, Steel grit Aluminum shots, aluminum rod.

These Products are used widely for deoxidation and secondary refining in the steel industry,

The main function is to refine grain, fix the nitrogen of steel, so as to significantly improve the impact toughness of steel, reduce the cold brittleness tendency and aging tendency, ensure that steel does not peel at high temperature and improve the high temperature corrosion resistance.

-

Wheel Type Aluminum Billets Continuous Casting Line

Application: This machine adopts wheel belt type continuous casting technology to produce High-End Aluminum Alloy Ingots/ billets, such as A356, which can be used for the automobile hub.

-

Aluminum Billets/ Ingots Casting Line

Application:Aluminum ingot casting line is an equipment to get predetermined weight and shape of aluminum ingots from qualified aluminum molten through the distribution system.

It integrates the distribution, cooling, automatic stripping and other processes of liquid aluminum. The equipment structure is simple, basically zero failure, long service life (< 7 years). The rated design output of aluminum ingot casting machine is 800 ingots/hour (the standard weight is 5-7kg/ ingot).

Characteristics of Casting Line

The Mold inside is smooth, the edges and corners are clear, the final ingots have super shape

Adopt the frequency control for the speed, the line working stable and aluminum has a good surface quality.

The structure of the casting machine is reasonable and maintenance is easy.

The working environment is good and efficiency is high.

-

Al-Zinc Alloy Rod CCR Line

Application: This production line adopts process of continuous casting and rolling to produce Aluminum Zinc Alloy.

Raw material: Primary aluminum ingots / electrolytic aluminum molten

-

Al-Ti-B Alloy Rod CCR Line

Application: This production line adopts process of continuous casting and rolling to produce Al-Ti-B alloy which is a kind of grain refinement agent for aluminum alloy casting.

Raw material: Primary aluminum ingots / electrolytic aluminum molten