-

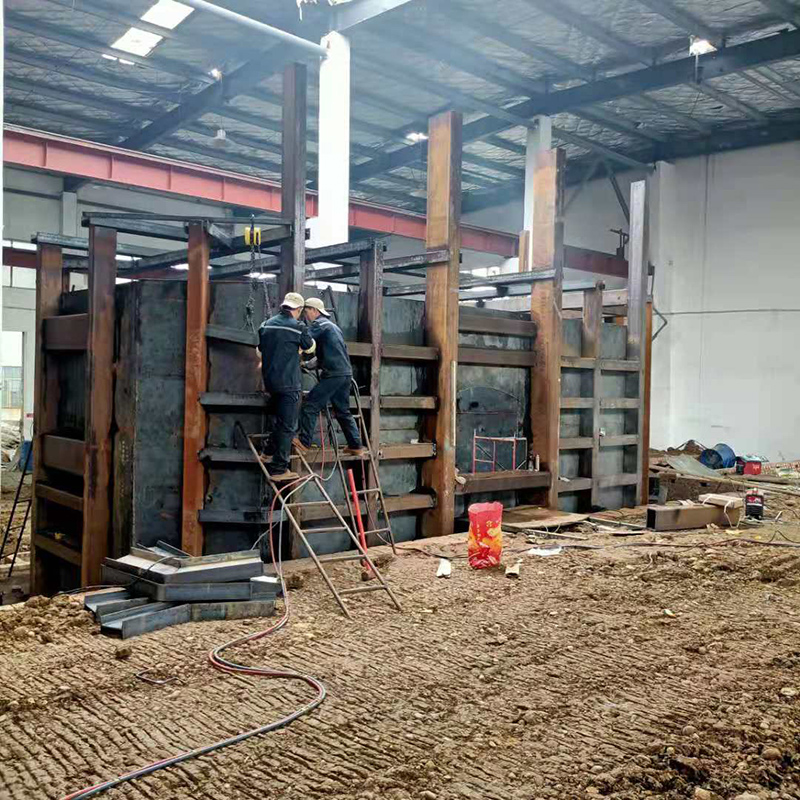

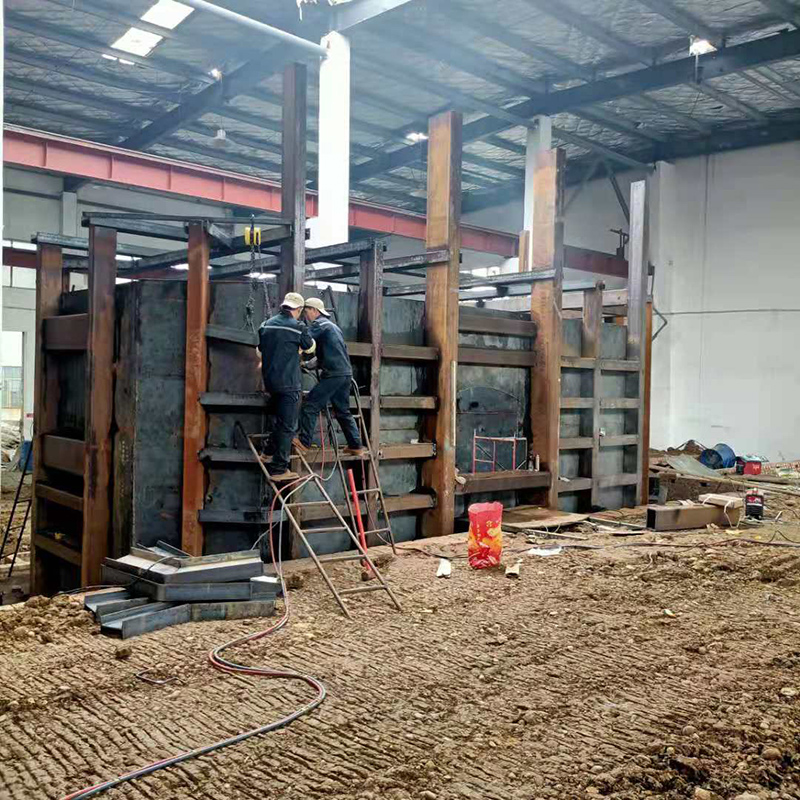

Melting and Holding Furnace

Our company has been meticulously committed to the R&D of special melting furnaces for a longer time. Rely on strong technical force and innovative design concept, we build our design purpose: energy-saving, reduce fuel consumption, improve production efficiency and product quality, improve working conditions, reduce environmental pollution, ensure the safe and reliable operation of the equipment and prolong the service life of the equipment.

In addition, in order to ensure the integrity of the casting and rolling production line, our company also provide high temperature combustion system, Regenerative combustion system, rotating Regenerative air preheater, silicon carbide metal combined air preheater, combustion fan, on-line degassing and filtration device, aluminum molten transfer ladle, etc. Except the above equipment, our company can not only provide the customized designation, manufacturing and construction according to user’s requirements, but also provide old furnace modify and energy-saving technical transformation, recommend the optimal scheme combined with the technological requirements of customers.

-

Cathode Shaft Melting Furnace and Tilting Holding Furnace

Application: The copper cathode shaft melting furnace is widely used for copper cathode smelting. The furnace has low maintenance rate, less equipment input, rapid convergency, and the capacity can be designed as the customers ‘need

Fuel: NG, LPG, LDO

Raw Material: High quality Copper cathode. The high-quality copper scrap also can be accepted, the utilization can be 20%-30%. But if the final copper rod will be used for fine wire drawing and electromagnetic wire (high quality enameled wire), we suggest the raw materials should be the copper cathode (LME Grade A)

-

Copper Scrap Tilting Refining Furnace

Application: The Copper scrap tilting refining furnace is widely used for copper scrap smelting. Because of good adaptability to raw materials, it also can be used as anode copper smelting. The refining furnace has low maintenance rate, less equipment input, rapid convergency, and the capacity can be designed as the customers ‘need (3T-60T)

Fuel: NG, LPG, LDO, FO, COAL GAS

Raw Material: Copper Scrap

-

Aluminum Refining Equipment

Function:

It is used for stirring the aluminum alloy molten, and mix all metal elements sufficiently to get a more uniform temperature and separate the slag out, also can reduce the labor cost and improve work efficiency. It has Permanent Magnet Stirrer and Electromagnetic Stirrer; the customer can choose according to different demand.

-

Aluminum Alloy Ingots Induction Heating Furnace

Application

The medium frequency induction heating furnace is installed between automatic shearer and continuous rolling mill, the main function is heating the aluminum alloy bar, so as to meet the temperature of the technology required before rolling.

-

Natural Gas De-oxidation system

NG Reduction system

This system is used for the copper reduction (de-oxidization). As usual, according to our traditional technology, we use the fresh trees for reduction, however, some countries cannot provide large quantity of trees, so we recommend to adopt the Natural Gas for reduction, so that can reduce the trees quantity, but can not 100% instead of trees, because need to ensure the reduction effect.

-

Pure Oxygen Combustion System

Application:

It is a new energy-saving technology developed and designed by our company in combination with the characteristics of industrial furnaces.

It is composed of burners, fuel decompression regulation system, oxygen decompression regulation system and controlling system.

At present, this technology has been used for copper scrap refining furnaces, more than 50% natural gas can be saved.

-

Copper Scrap Stationary Refining Furnace

ApplicationThe Stationary Refining (reverberatory) furnace is widely used for copper scrap smelting. Because of good adaptability to raw materials, it also can be used as anode copper smelting. The refining furnace has low maintenance rate, less equipment input, rapid convergency, and the capacity can be designed as the customers ‘need (15T-120T), the refining technology is easier than other technology, so it is still adopted by most users.

Fuel: NG, LPG, LDO, FO, COAL GAS

Raw Material: Copper Scrap