-

3-roller type Aluminum and aluminum alloy Rod CCR Line

Application: This production line adopts process of continuous casting and rolling to produce Round Aluminum rod or aluminum alloy Rod for Electrical Purpose.

Raw material: Primary aluminum ingots/sow/ electrolytic aluminum molten/aluminum scrap from wire or cable

Fuel: NG/LPG/LDO/FO/COAL GAS

Rolling mill Lubricant: Rolling mill gears are lubricated by gear oil

Bearings and rollers of rolling stands are lubricated by emulsion oil

-

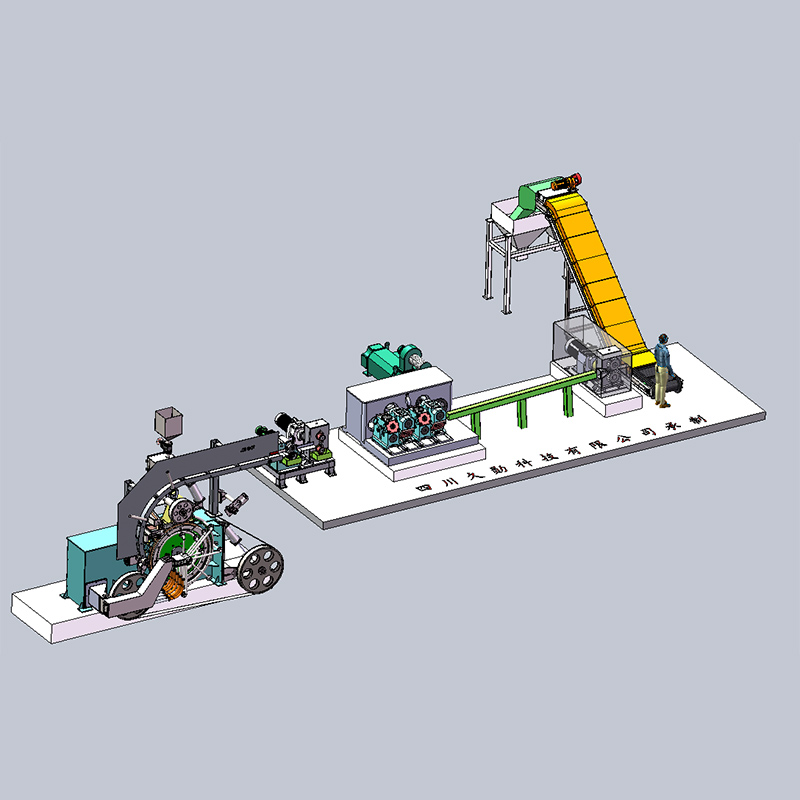

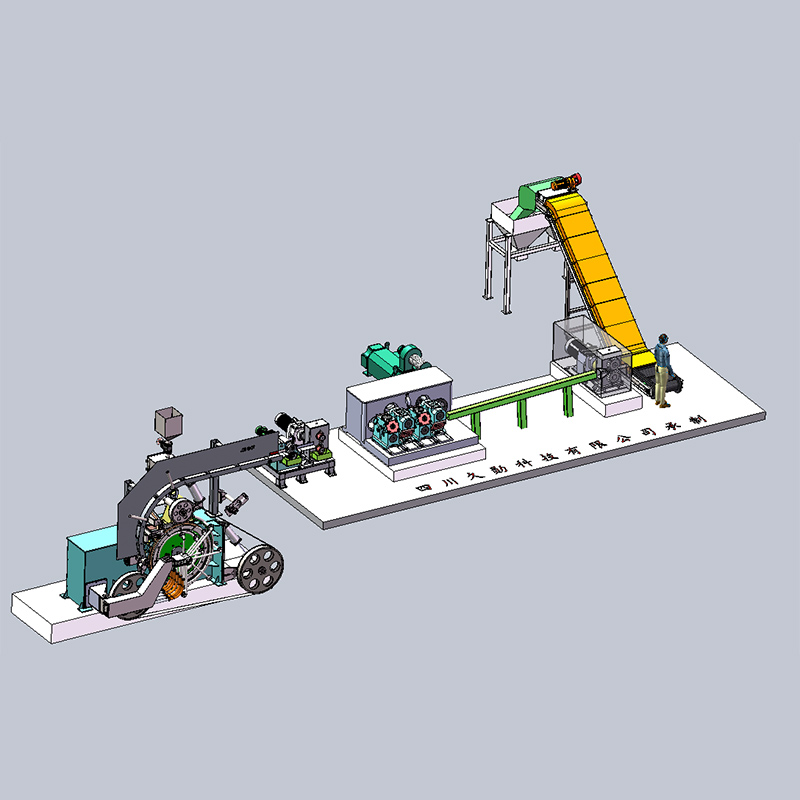

Aluminum Cut Wire rod Shot Production Line

Application :The typical Continuous Casting and Rolling Line is used for producing all kinds of deoxidized aluminum products, such as aluminum shots, Steel grit Aluminum shots, aluminum rod.

These Products are used widely for deoxidation and secondary refining in the steel industry,

The main function is to refine grain, fix the nitrogen of steel, so as to significantly improve the impact toughness of steel, reduce the cold brittleness tendency and aging tendency, ensure that steel does not peel at high temperature and improve the high temperature corrosion resistance.

-

Wheel Type Aluminum Billets Continuous Casting Line

Application: This machine adopts wheel belt type continuous casting technology to produce High-End Aluminum Alloy Ingots/ billets, such as A356, which can be used for the automobile hub.

-

Aluminum Billets/ Ingots Casting Line

Application:Aluminum ingot casting line is an equipment to get predetermined weight and shape of aluminum ingots from qualified aluminum molten through the distribution system.

It integrates the distribution, cooling, automatic stripping and other processes of liquid aluminum. The equipment structure is simple, basically zero failure, long service life (< 7 years). The rated design output of aluminum ingot casting machine is 800 ingots/hour (the standard weight is 5-7kg/ ingot).

Characteristics of Casting Line

The Mold inside is smooth, the edges and corners are clear, the final ingots have super shape

Adopt the frequency control for the speed, the line working stable and aluminum has a good surface quality.

The structure of the casting machine is reasonable and maintenance is easy.

The working environment is good and efficiency is high.

-

Al-Zinc Alloy Rod CCR Line

Application: This production line adopts process of continuous casting and rolling to produce Aluminum Zinc Alloy.

Raw material: Primary aluminum ingots / electrolytic aluminum molten

-

Al-Ti-B Alloy Rod CCR Line

Application: This production line adopts process of continuous casting and rolling to produce Al-Ti-B alloy which is a kind of grain refinement agent for aluminum alloy casting.

Raw material: Primary aluminum ingots / electrolytic aluminum molten

-

2-roller type Aluminum and aluminum alloy Rod CCR Line

Application: This series of aluminum alloy CCR line belongs to the typical and high configuration to meet the individual demand of customers.

Raw material: Primary aluminum ingots/sow/ electrolytic aluminum molten/aluminum scrap from wire or cable

Fuel: NG/LPG/LDO/FO/COAL GAS